SERVICE

OUR BUSINESS

-

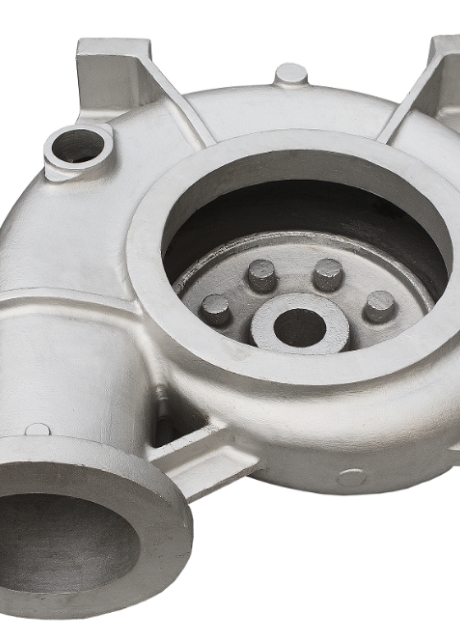

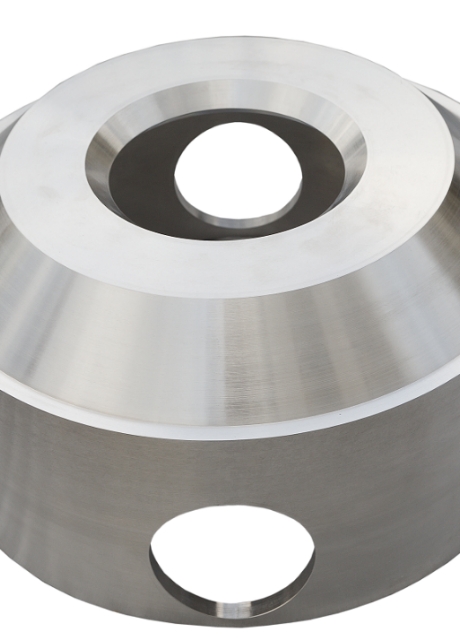

Stainless cast steel

Our products are resistant to corrosive environments such as strong acids and strong alkalis.

With our extensive experience in casting, we are capable of manufacturing products in various 3D shapes.

Additionally, we are also capable of manufacturing products with dual-phase and precipitation-hardening alloys.Products Special steel materials (martensitic, austenitic, two-phase, precipitation hardening) Main uses - Pump parts (casing, impeller, cover, plate, etc.)

- Valve parts (body, cover, valve, etc.)

- Water treatment parts (upper water treatment related, sewage treatment related, etc.)

- Water gate parts (sieve, roller, etc.)

- Parts for paper manufacturing plants (conveyor, screen, pump, boiler, etc.)

- Parts for sugar manufacturing plants (die plate, pump, etc.)

- Parts for centrifugal separators

-

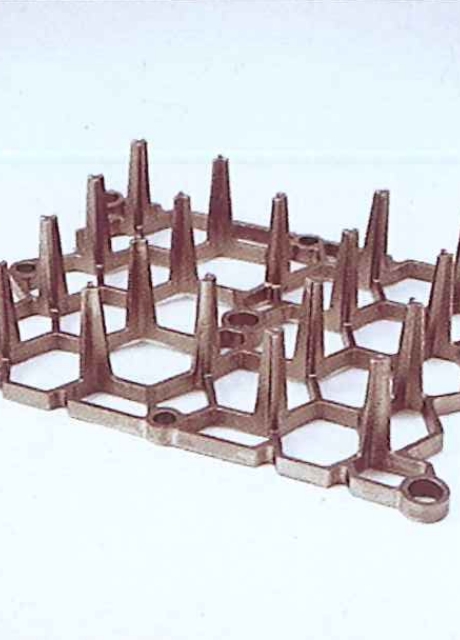

Heat resistant cast steel

Our products are capable of withstanding environments exceeding 1000℃.

We select the optimal materials based on required strength at high temperatures, and are capable of manufacturing products that can withstand high-temperature corrosion caused by chlorine, sulfur, and other factors.Products Special steel materials (ferritic, austenitic, high-alloy) Main uses - Parts for incinerators (stoker furnaces/rotary kiln furnaces/fluidized bed furnaces)

- Boiler combustion parts (burner parts/supporting hardware)

- Equipment parts for cement plants (AQC parts/refractory metal fittings/preheaters)

- Parts for petroleum refining equipment (tube sheets/tube support hardware)

- Heating furnace parts for electric furnaces/blast furnaces

- Industrial furnace parts (furnace transport parts)

- Various heat treatment fixtures (trays/pierces)

-

Wear resistant cast steel

We also address tribology problems such as erosion and wear. We propose surface modification materials such as thermal spraying and buildup to address various wear problems.

In addition, we can manufacture products with hard materials with HV 800 or more or products with excellent toughness.Products Special Steel Materials (High Cr cast steel, High Cr cast iron, High Mn cast steel) Main uses - Pump parts (slurry pumps, dredging pumps, concrete pumps)

- Equipment parts for thermal power plants (ash handling parts, coal crushers, pulverizer mill parts)

- Equipment parts for paper mills (disintegrator parts, conveying parts)

- Dust collector parts, kneading machine parts

- Guide rollers for rolling mills, general industrial parts

- Crusher parts (hammers, grates, liners)

-

Production capacity

We have established a production system that can meet the needs of various customers, from small to large items, and from small to large lot sizes. Please feel free to documents us for products that exceed the capacities listed below.

Max. production capacity

Height 1,000mm Length 2,000mm Frames 600mm x 800mm x 1,500mm Max. weight 800kg

FACILITIES

-

Wood pattern factory Our on-site pattern-making factory with model machining equipment can handle patterns and resins up to a size of 1000x1000. -

Alkaline Phenolic Molding factory This is a molding facility that solidifies sand by kneading an alkaline resin and hardener into artificial sand.

Furan molding is also operated simultaneously, and it can handle various product shapes. Sand used is recycled using a sand reclamation system -

High frequency induction furnace This equipment utilizes electromagnetic induction to efficiently and rapidly dissolve metals.

It uses electric heating to dissolve, resulting in reduced CO2 emissions and environmental considerations. -

Optical emission spectrometer This is an instrument used to analyze the chemical composition of products.

By irradiating metals with light and measuring the wavelength and emission intensity of the element, the type and content of the element can be determined.

It is also capable of analyzing special elements such as tungsten (W) and cobalt (Co).

Facilities and equpiment

| Melting | High frequency induction furnace | 1t | 2 units |

|---|---|---|---|

| 0.5t | 2 units | ||

| Heat treatment | LPG furnace |

Maximum temperature: 1,200℃ Maximum weight: 4 tons capacity Maximum volume: 2,300W×1,600D×1,000H Water tank volume: 2,000W×1,500D×1,200H |

1 unit |

| Electric furnace (trolley) |

Maximum temperature: 1,200℃ Maximum weight: 2-ton capacity Maximum volume: 1,500W×1,000D×600H |

1 unit | |

| Electric furnace (top cover) |

Maximum temperature: 1,100℃ Maximum weight: 0.5 ton capacity Maximum volume: 700W×700D×700H |

1 unit | |

| Furan molding | Automatic mixing equipment for organic self-hardening sand 1 set | 1 unit | |

| Regenerating equipment for organic self-hardening sand 1 set | 1 unit | ||

| Alkaline Phenolic molding | Alkaline phenolic sand mixing equipment 1 set | 1 unit | |

| Alkaline phenolic sand regeneration equipment 1 set | 1 unit | ||

| Fettling | Shot blast | Turntable | 1 unit |

| Tumbler | 1 unit | ||

| Acid washing equipment | 1 unit | ||

| Quality control and testing | Emission spectrometer | 1 unit | |

| Metal microscope | 1 unit | ||

| Durometer | HS.HB.HR | 1 unit | |

| 3D CAD | 1 unit | ||

| Casting simulation software | 1 unit | ||

| Tensile testing machine | 1 unit | ||

| Microscope | 1 unit | ||

| Non-destructive testing equipment | MT.UT.RT | 1 unit | |

| Wood pattern | Rapid prototyping machine | for Pattern | 2 units |

| Others | Dust collector |

Inverter control 100㎥: 1 unit 500㎥: 2 unit 630㎥: 1 unit |

4 units |

| Compressor | Inverter control | 4 units | |

2022年3月時点